robotextile

Technology

Inexpensive, robust and user-friendly textile robots pick up the separated fabric layer and set it down again safely and smoothly at the desired position.

Process

All fabrics and textiles have a “character of their own”. In numerous trials and scientific work, we have mastered the complexity and challenge in the applications.

Binding offers are made after careful examination and selection of the appropriate gripper technology. For this purpose, please send us your original fabric stacks after prior consultation.

We attach great importance to satisfied and long-term customer relationships.

robotextile robot cell

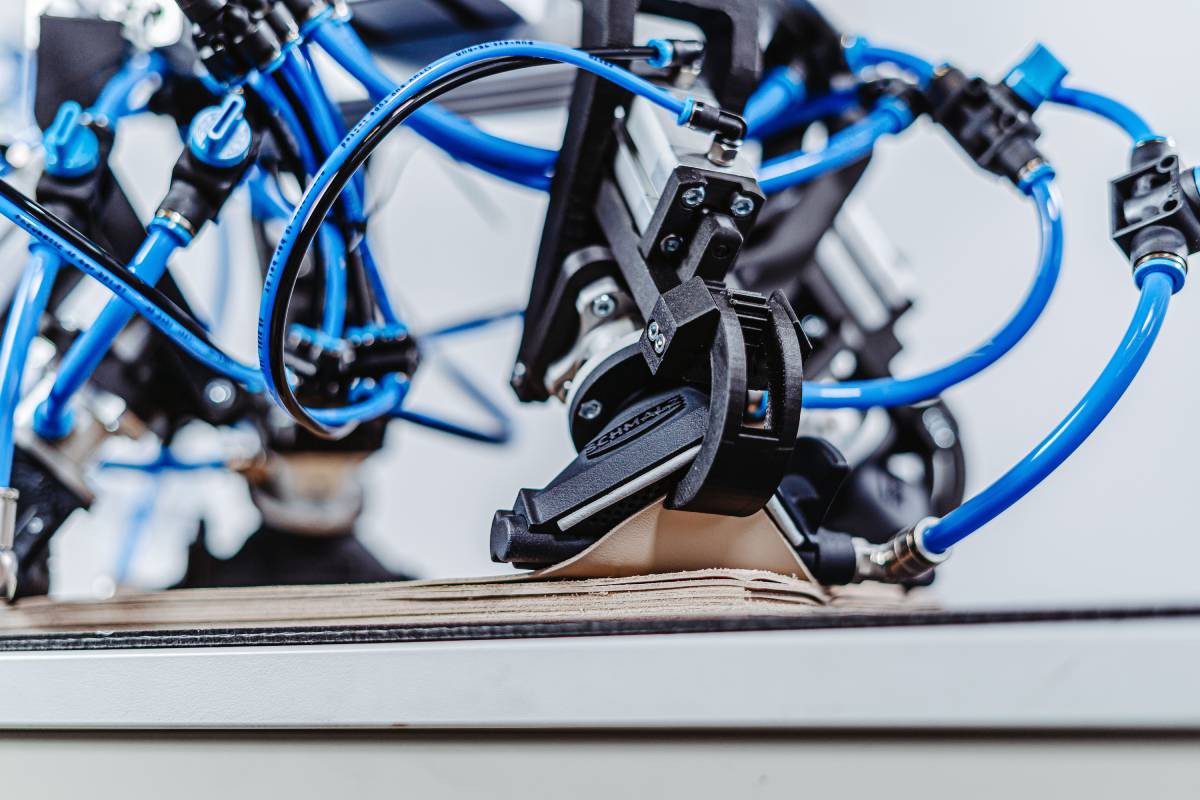

Ready for use and market-tested: The system solution consisting of a small robot and a special gripper removes individual layers of fabric from the blank stack, separates the layer and feeds it to the next production step – without picking up the bottom layer of fabric.

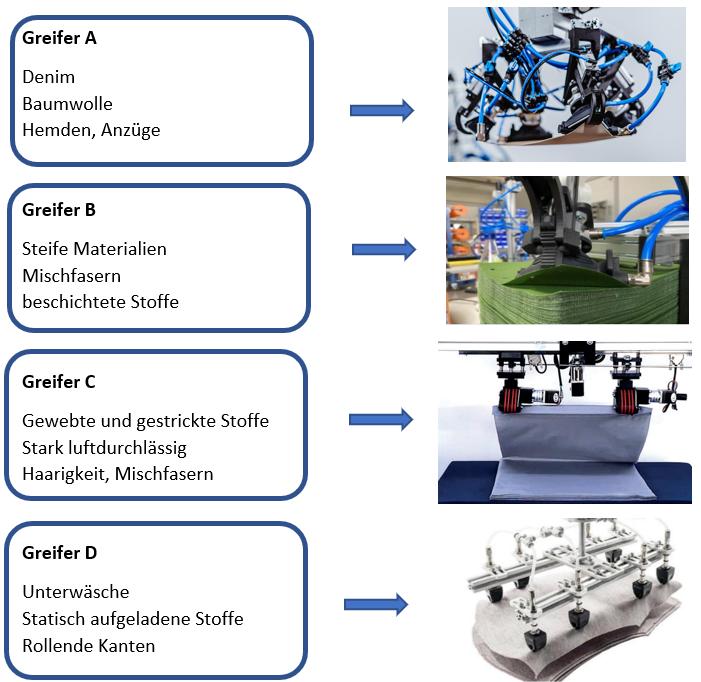

The core of the robotic cell is the textile gripper that fits the application:

- by air flow

- by adhesion

- by rubber roller

- by finger haptics

All textiles are evaluated and examined for the gripping method: Thickness, bending stiffness, hairiness, air permeability, weight, static charge, rolling edges.

The standard KUKA Scara robot has a working diameter of 1600mm diameter and 5 kg payload. Depending on the layout and general conditions, cycle times of 2 to 4 seconds per fabric layer are possible. The robot can be intuitively parameterised by the factory personnel via a graphical operator panel.

To suit customer requirements, larger KUKA robots can be selected at extra cost, or even a so-called “cobot”. This robot has integrated robot safety technology for direct cooperation with humans.

The robot cells are delivered ready for operation with CE within Europe. The commissioning can be done by the customer with our online help and is optimally supported by the robotextile team. The cells are configured to be self-sufficient and ready for use.

robotextile robot cell options

The cells can be supplied with a table and safety device or just mounted on a mobile base. The grippers are mounted ready for operation.

Optional gripper changing systems are available, or multifunctional grippers for a wide range of fabrics.

Optional camera systems detect the position of the fabric stacks and guide the robot to the correct position.

Optionally, the robots can be guided and programmed manually for teach-in. This can be done by the production personnel.

For plant manufacturers and textile machine manufacturers, we also offer the grippers separately on request, without robots. Please enquire.

Optionally, online training can be offered and new fabric types can be taught in together.

Optional holders for the fabric stacks can be offered.